Introduction To Chain Maintenance Of Excavator

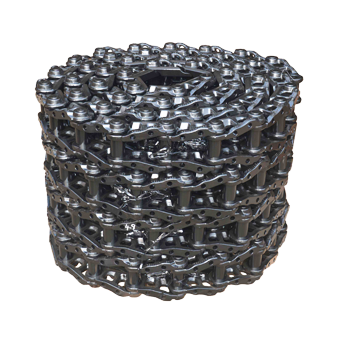

Any construction site is inseparable from excavators. Now let’s briefly share the maintenance of excavator track chain assy. 일반적으로, it is normal for the excavator track chain assy to extend by 1 / 50 during operation. If the extension is excessive, the number of meshing teeth of the sprocket will be reduced, resulting in noise and damage to the chain. The loose edge sag value l can be used to reflect the elongation of the chain. The L value is generally set as 2 ~ 4% of the center distance between the two sprockets. In case of excessive sag, remove the sprocket cover and adjust it with a tensioning device.

1. The side drive gear is an external open drive, with low speed and large load, which is easy to be contaminated by dust and sludge. Before starting, the lubricating oil shall be poured on the gear with an oil pot, and the dust and dirt shall be removed once a week to prolong its service life. Do not apply grease to the side drive gear, because the grease will bind a large amount of sand and dust, but accelerate the wear of the gear.

2. In addition, the big gear ring and the drive wheel are fixed with bolts, which shall be checked and tightened once a week. The drive chain is also the final transmission part of the excavator. Its transmission load is very large, and it is impacted by driving and braking, so it needs careful maintenance.

3. The sleeve roller chain will elongate during operation, which is caused by the gap caused by the wear between the sleeve and the roller. 그러므로, it is necessary to fill the gap between the chain plate with thinner lubricating oil. The oil shall be filled on the loose side of the chain so that the oil can enter the gap between the chain plate. After that, the excess oil shall be wiped off with cotton yarn. Do not apply butter or high viscosity oil on the chain for lubrication, That will damage the excavator track chain assy and excavator sprocket and segement due to the adhesion of sand and dust.

4. If the chain is seriously polluted, it should be removed, cleaned with gasoline, soaked in lubricating oil for half an hour, then fished out to wipe off the excess oil and continue to be loaded for use.