Brief Introduction Of Excavator/Bulldozer Front Idler

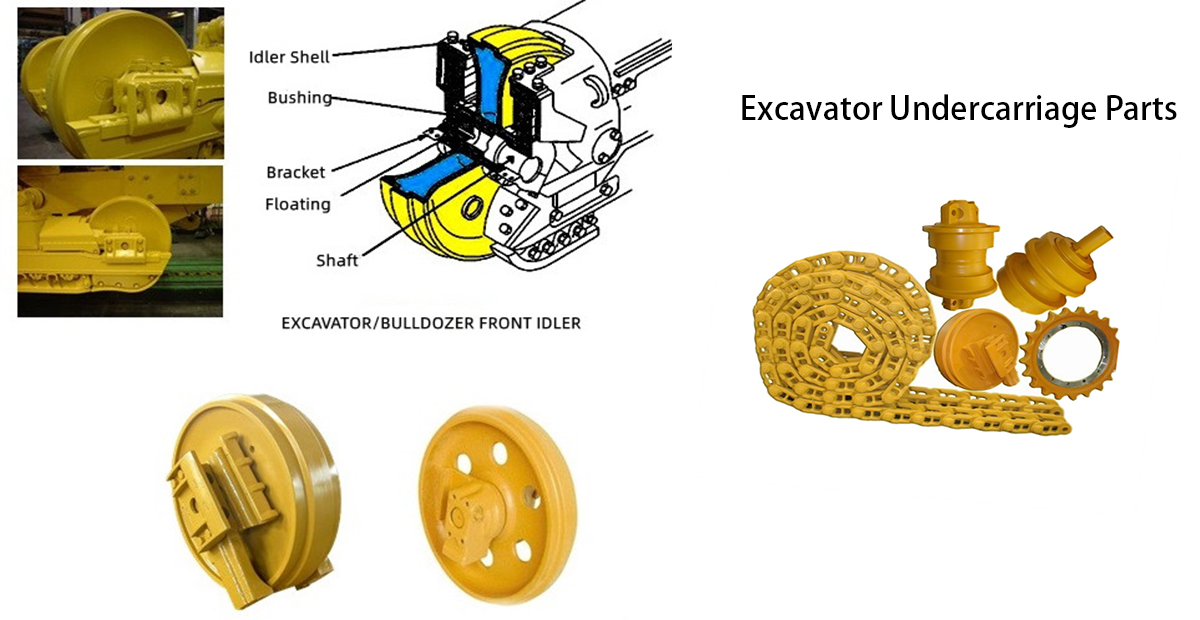

The excavator front idler is mainly composed of the idler shaft, the idler blocking plate, the front idler body and some standard parts (iron sleeve, cylindrical pin, duplex metal bushing, bolt spring, gasket floating, oil seal floating ring, O ring seal).

The main function is to guide the correct winding of the track, and use the tensioning gear to make the excavator front idler move to adjust the tension of the track. So the front idler is not only the idler of the track, but also the tensioning wheel in the tensioning device.

How To Distinguish The Idler Group From The Excavator/Bulldozer Sprocket? See Difference Of Them As Below:

1)The one that turns forward in the front is the idler wheel,and inside the guide wheel is a toothless wheel.

2)Behind the excavator front idler is the drive, the drive has a semicircular iron plate, the outside is a round, inside has teeth.

The surface roughness of guide wheel shaft Ra1.6 is out of tolerance. If the roughness of the front idler shaft is excessive, there are many metal ridges on the shaft surface, which destroy the integrity and continuity of the lubricating oil film between the shaft and the sliding bearing.When working, a large number of metal abrasive chips will be produced in the lubricating oil, which increases the surface roughness of the shaft and bearing, worsens the lubrication state, and causes the wear of the front idler shaft and the sliding bearing in serious cases.

How To Replace The Excavator Idler Wheel?

1)Remove the crawler of the excavator. Remove a single valve at the place of the grease nipple, let the grease out, use the bucket to push the guide wheel in, let the track as loose as possible. If the excavator is the above 150, then remove the track pin. If it is more than 150, then use the bucket to hook the crawler down, remember to remove the single valve, otherwise it is not good to remove the track, and more difficult to install.

2)Install the front idler. The excavator front idler installation is the same as the general wheel installation method. Use a jack to prop up the excavator, and then use a screwdriver to unscrew it. After it is removed, install the new wheel and grease it, that is, complete the installation.

The butter gun is used to pour the butter into the butter cylinder through the butter nozzle, so that the piston extends to push the spring, and the front idler moves left to tighten the track. The jacking spring has an appropriate stroke, and the spring is compressed to play a cushioning role when the tightening force is too large; With the excess tension gone, the compressed spring pushes the guide wheel into place.

In this way, it can ensure sliding along the track frame to change the wheel pitch, ensure the disassembly of the track, reduce the impact of the walking process, and avoid the derailment of the track chain for excavator. The damage of the front idler assembly is mainly caused by poor lubrication of the guide wheel shaft.