La estructura principal y función de los rodillos inferiores

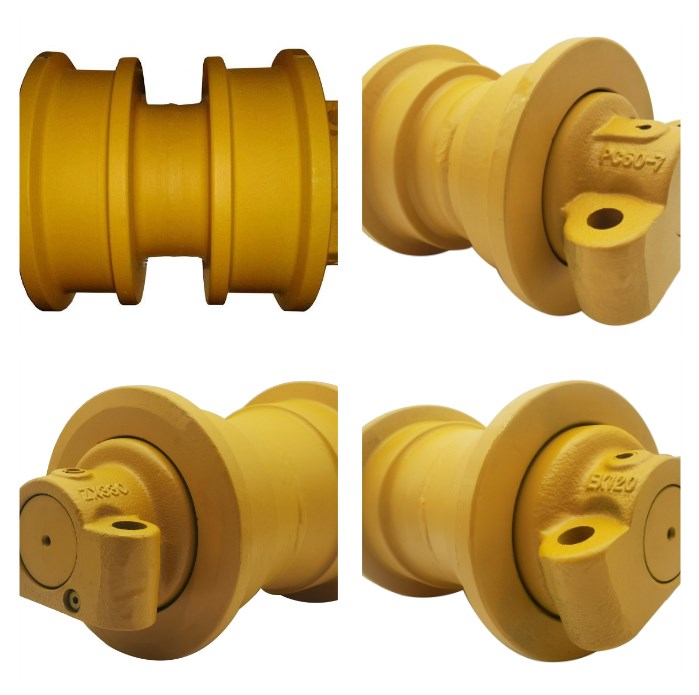

The bulldozer rodillo guía is an important component of the undercarriage system in excavators and bulldozers. Su función principal es soportar el peso del bulldozer y excavadora., permitiendo que las pistas se muevan a lo largo de los rodillos. Los componentes principales del rodillo inferior incluyen el cuerpo de la rueda., eje del rodillo guía, cojinete, anillo de sellado, Tapa final, y otras partes estructurales relacionadas. Excavador track rollers are generally painted black, mientras que los rodillos de las excavadoras suelen estar pintados de amarillo.

The track roller is fixed under the roller frame with screws to support the machine’s weight and distribute it across the track plates. It can transfer the weight of the locomotive set to the ground and roll on the track. To prevent derailment, it can also prevent lateral relative movement of the track. track rollers often work in mud, water, ash, and sand, enduring strong impacts and extremely harsh working conditions, leading to easy wear of the wheel rim. Por lo tanto, the requirements for buttom rollers include wear resistance and reliable bearing seals.

Lower rollers can be divided into single-flange and double-flange types based on their structure. Por ejemplo, D65-8 track roller is double flange while EX120/PC50-7/ZX330 are single flanges. They employ both sliding bearings and rolling bearings. The rims of the track rollers/bottom rollers/lower rollers are hardened, with a hardness of 355-440HB. In the undercarriage, particularly when spacers are installed to increase rigidity, the resulting cavities can easily become clogged with dirt, obstructing the track rollers. Running on soaked soil can also easily clog the track rollers. Por lo tanto, some tracked bulldozers are equipped with track roller guards with reinforcing ribs on the outside of the undercarriage frame.